Designing Temporary Spaces for Maximum Comfort and Efficiency

Modern temporary spaces combine rapid installation with genuine comfort and efficiency, no compromises required. Whether you’re a facilities manager planning extra warehouse capacity, a school expanding for growing enrolment, or a retailer recovering from unexpected disruption, today’s modular buildings deliver environments where people genuinely want to work, learn, shop, and gather.

Here’s how to achieve that same standard when designing temporary spaces for your own project.

Why Comfort and Efficiency Matter More Than Ever

Businesses face an impossible equation: traditional construction takes 18-24 months whilst market demands shift in weeks, sometimes days.

Warehouse vacancy rates hover around 7%, but when you need space, you need it now, not in six quarters. Meanwhile, employees and customers have raised their expectations dramatically. Nobody tolerates substandard environments anymore, whether permanent or temporary buildings.

The post-pandemic landscape accelerated everything:

- Hybrid working models demand flexible spaces that adapt within weeks, not years.

- Net Zero commitments require sustainable solutions; inefficient temporary structures undermine your entire carbon strategy.

- Economic uncertainty makes long-term property commitments genuinely risky when market conditions change overnight.

- And crucially, the technology exists to deliver genuinely comfortable temporary environments without the delays, costs, or compromises of traditional construction.

What Comfort Really Means in Temporary Buildings

● Thermal Comfort

Thermal comfort keeps temperatures stable, typically 18 – 21°C for offices and 15 – 18°C for warehouses, whilst controlling humidity to prevent condensation and that clammy feeling that makes concentration impossible. Suitably engineered sealing eliminates those annoying draughts that make people reach for jumpers even with the heating blasting.

Overheating requires excessive cooling. Cold spots drive heating costs through the roof. Staff spend mental energy managing discomfort instead of focusing on work.

● Acoustic Comfort

Acoustic comfort blocks external noise whilst managing internal sound. Educational spaces need speech clarity, or learning suffers. Offices require concentration-friendly quiet, or productivity plummets. Hospitality venues demand conversation-level acoustics or guests leave early.

External noise intrusion from traffic, construction, or industrial operations destroys concentration and creates genuine stress. Internal echo and reverberation make speech unintelligible, forcing people to shout and create exhausting environments.

● Visual Comfort

Visual comfort balances natural daylight with appropriate artificial lighting. Glass panels flood interiors with natural light, proven to improve well-being, productivity, and even sleep quality.

Insufficient lighting causes eye strain, headaches, and errors. Harsh artificial lighting without natural daylight creates depressing environments where nobody wants to spend time.

● Air Quality

Fresh air circulation meeting Building Regulations Part F standards prevents that stuffy, headache-inducing atmosphere whilst filtering dust and pollutants. Proper ventilation creates healthy, productive environments where people can actually breathe comfortably.

What Efficiency Delivers in Temporary Buildings

● Energy Efficiency

Energy efficiency starts with proper insulation in the roof and walls. Good insulation can achieve Energy Label A ratings, and can help to cut your running costs.

● Space Efficiency

Clear-span designs eliminate columns for 100% usable floor area, no awkward obstructions disrupting workflows or wasting expensive square meterage. Mezzanines double capacity within the same footprint, maximising value from every square metre.

Wasted space costs you twice: once in unnecessary structure size, again in heating, lighting, and maintaining areas you can’t actually use productively.

● Operational Efficiency

Rapid installation means structures become operational in weeks, not months. Minimal maintenance requirements protect ongoing productivity. Adaptable layouts accommodate changing needs without expensive refits. Relocation capability protects your investment when circumstances change.

Five Core Design Principles for Temporary Spaces

1. Design for permanence, build for flexibility.

Structures should feel permanent whilst remaining adaptable. Quality standards match or exceed permanent construction, but bolt-together assembly enables future modifications without demolition and reconstruction costs.

User acceptance, long-term viability, and investment protection all depend on this principle. Staff and customers immediately sense quality, or lack thereof. Substandard temporary spaces signal instability and undermine confidence in your operation.

2. Prioritise the building envelope.

The envelope, roof, walls, and floor determine virtually all comfort and energy performance. Everything else depends on getting this foundation right.

Proper insulation specifications eliminate heat loss. Air tightness prevents draughts and condensation. Weather resistance against wind, rain, and snow protects interiors.

Thermal bridging elimination ensures consistent performance across the entire structure.

3. Plan for human experience.

Design extends beyond functional requirements to consider how people actually move through and use spaces. Poor circulation creates congestion and frustration. Unclear sight lines cause wayfinding confusion. Accessibility failures exclude customers and violate legal requirements.

Circulation flows prevent bottlenecks at entries, corridors, and high-traffic zones. Sight lines aid intuitive navigation. Accessibility compliance meets Disability Discrimination Act (DDA) and Building Regulations Part M standards, ensuring everyone can use your space comfortably and legally.

4. Integrate systems holistically.

HVAC, electrical, and plumbing are designed together from the start to avoid retrofit inefficiencies that plague buildings where heating gets added after walls are up or lighting retrofitted around pre-existing structures.

Fragmented design creates uncomfortable hot spots, cold zones, inadequate lighting in key areas, and maintenance nightmares. Integrated systems work together efficiently, reducing energy consumption whilst improving comfort.

Smart building technology and energy management systems future-proof your investment, enabling optimisation as technology evolves.

5. Embrace modularity strategically.

Module sizing balances transport efficiency with space efficiency. Connection methods enable expansion when growth demands it. Standardisation, where appropriate, keeps costs controlled; customisation, where needed, ensures your space actually serves your specific requirements.

Your Planning Framework for Designing Temporary Spaces

Step 1: Define Functional Requirements

Identify what you’ll use the space for: manufacturing, retail, education, hospitality, or storage. Calculate how many people are at peak times, on average, and at minimum. Underestimating causes overcrowding and safety issues.

Consider operating hours; 24/7 operations differ vastly from seasonal use. List special requirements like heavy machinery, food preparation, or hazardous materials. Discovering these during installation becomes extremely expensive.

Work out which areas need proximity (kitchens near dining) and which need separation (noisy production away from quiet offices).

Step 2: Conduct Site Surveys

Measure exact site dimensions; guessing causes delays. Check ground conditions: weight capacity, drainage, contamination. Look for slopes, flood risks, and obstacles like buildings, trees, or underground pipes.

Check truck access, width, height clearance, and turning space. Poor access means manual handling and increasing costs.

Step 3: Plan Climate Control Strategy

Choose heating with floor units, frame-mounted, or overhead.

Choose a suitable fuel to balance costs: electric (simple, pricier running costs), gas (cheaper running, complex installation), or heat pumps (higher upfront, excellent long-term savings).

Calculate the right capacity. Too little means discomfort; too much wastes money. Different areas and warehouses need different temperatures than offices. Use programmable controls and sensors to prevent heating empty spaces.

Cooling ranges from opening windows to mechanical ventilation to air conditioning.

Proper insulation achieves BREEAM ‘Very Good’, Energy Label A, and strong EPC (Energy Performance Certificate) ratings. Poor specification leads to years of high bills and complaints.

Step 4: Map Circulation Flows

Plan entries and exits with enough capacity and weather protection. Design main corridors with proper widths. Keep forklifts and pedestrians separate.

Identify bottlenecks at doorways and waiting areas. Plan for peak times, lunch, shift changes, and events. Ensure accessibility with step-free access, doorways, and wheelchair turning space.

Step 5: Select Materials and Insulation

Structural materials include lightweight aluminium (strong, reusable), steel connections, and engineered timber.

Wall and roof panels sandwich insulation between protective layers. Glazing ranges from double to triple-glazed. Flooring includes raised floors (concealing services), heavy-duty wooden floors (supporting forklifts), or concrete slabs (maximum strength).

Material choices affect lifespan, comfort, energy costs, and maintenance. Cheap materials create ongoing costs exceeding initial savings.

Step 6: Plan Lighting and Acoustics

Natural light saves energy and improves well-being. Aim for 20-30% glazing. Roof lights work for high buildings.

LED lighting cuts energy use 80-90%. Match brightness to tasks. Sensors adjust automatically.

Acoustic design controls echo, ensures clear speech, maintains comfortable background noise, and stops sound from travelling between areas. Poor acoustics reduce productivity and increase stress.

Step 7: Consider Regulatory Requirements

Planning permission typically isn’t needed for under 28 days. Longer stays need 8 – 13 week applications. Smaller buildings (under 1,000m², under 5m height) sometimes get exemptions.

Building Regulations cover structure, fire safety, acoustics, ventilation, energy efficiency, and accessibility.

As experienced suppliers, Neptunus assists clients through the planning and compliance process. Inexperienced suppliers cause delays and expensive fixes.

Step 8: Develop Scalability Forecasts

Growth plan: conservative (10-20%), expected (30-50%), or ambitious (doubling). Think one, three, five years ahead.

Modular building systems grow easily, add sections, connect buildings, or add mezzanines. Building too small forces expensive early expansion; too large wastes money on unused space.

Material Choices That Deliver Performance

Insulated Panels

Sandwich panels have insulation sandwiched between metal outer layers, providing both strength and temperature control creating thinner walls with better insulation.

These panels achieve excellent insulation ratings, helping you reach Energy Label A and BREEAM standards whilst staying effective through multiple uses and moves.

Flooring Systems

Insulated raised cassette floors conceal services elegantly whilst providing thermal performance, ideal for offices and retail, where aesthetics and comfort both matter. They would also support heavy industrial use, including forklifts and pallet storage.

Concrete slabs offer the highest load capacity and longest lifespan for heavy industry, cold storage, or applications with extreme durability requirements.

Modular Components

Standardised modular buildings are bolt-together with components that require no welding or permanent modification, enabling future reconfiguration, expansion, or complete relocation. Bay increments enable flexible sizing tailored to your exact requirements.

Benefits include 90%+ waste reduction (components dismantle cleanly without demolition waste), material conservation through reuse rather than disposal, and infinite aluminium recyclability, protecting end-of-life value.

True circular economy value: structures serve multiple applications across decades, then materials are recycled completely rather than entering landfill.

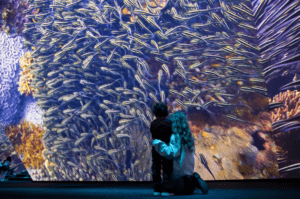

Real-World Excellence with BBC Earth Experience

The Challenge

Producer Moon Eye Productions needed a venue for a groundbreaking 24-month immersive attraction featuring Sir David Attenborough’s narration in central London.

The location presented significant obstacles with heavy external traffic noise, limited space for construction, and the need for exceptional structural height to create an immersive experience across Earth’s seven continents.

The Objective

The BBC Earth Experience required complete visitor immersion through multi-angle projection screens and sophisticated audio.

Key objectives included complete soundproofing to block external noise whilst maintaining crystal-clear internal audio, climate control ensuring visitor comfort during 60 – 90 minute experiences across all seasons, exceptional height (15m structure with 12.5m internal clearance) creating immersive scale, total lighting control for projection quality, and comfortable visitor facilities.

The Solution

We designed a comprehensive temporary structure solution combining advanced insulation, acoustic engineering, and climate control systems.

Hipertec roof and wall panels provided exceptional soundproofing capabilities. Reusable insulated wooden flooring with integrated insulation panels delivered thermal performance.

The roof structure was engineered to support multiple suspended projection screens whilst maintaining structural integrity.

Temporary Structures Used

The Evolution I structure covering 2,400m² served as the main experience space, featuring Hipertec panels for superior acoustic and thermal performance.

A separate Evolution III structure (600m²) with mezzanine provided ground-floor reception and gift shop with first-floor offices and facilities. Both structures were certified for multi-year use whilst remaining fully dismantlable and reusable.

The Result

External London noise was completely blocked, creating a pristine internal sound environment. Consistent 18 – 21°C temperatures were maintained throughout the 24 – month operation. The structures met full UK insulation compliance standards whilst delivering permanent-venue quality performance.

Visitors reported complete immersion in the natural world, with the temporary structure’s performance indistinguishable from purpose-built permanent venues, proving comfort, acoustics, and atmosphere don’t require permanent construction.

Why Partner with Neptunus

Designing comfortable, efficient temporary spaces demands a partner with proven expertise, advanced technology, and quality commitment.

Founded in 1937. Third-generation family business. Global experience across the UK, Europe, and worldwide projects spanning education, retail, logistics, sports, hospitality, and emergency applications.

Industry-Certified Standards

- ISO 9001:2015: Quality management, consistent outcomes

- ISO 14001:2015: Environmental management, sustainability support

- CHAS (Contractors Health & Safety Assessment Scheme): Health and safety competence verification

- MUTA (Made Up Textiles Association): Industry best practice adherence

In-house design teams collaborate on your requirements. Controlled factory manufacturing ensures quality. Experienced crews deliver structures operational in days to weeks.

Ongoing support includes maintenance, modifications, extensions, and 24/7 emergency response. Systematic deconstruction protects component reusability and restores sites completely.

Permanent-Quality Performance

- Energy Label A ratings.

- BREEAM capabilities.

- Operational lifespans from a few months to several years.

Comfort focus across thermal, acoustic, visual, and air quality dimensions. Flexibility enables adaptation, expansion, and relocation throughout.

Advanced Modular Systems

- Evolution: Hydraulic lifting, up to 50m clear spans, 4 – 15m heights

- Flexolution: Sustainable, bolt-together, BREEAM-rated, easily relocated

- Alu Hall: Rapid deployment for events, emergency response, seasonal facilities

Transform Your Space Requirements Into Reality

Comfort and efficiency aren’t compromises in designing temporary spaces; they’re achievable outcomes when you follow proven frameworks, specify appropriate materials, integrate climate control and acoustics properly, and partner with experienced suppliers holding genuine certifications.

Contact Neptunus today at +44 1604 593820 to discuss your requirements.

Our experienced team provides comprehensive support from initial consultation through design, regulatory approvals, installation, and ongoing maintenance.

Transform your temporary space requirements into comfortable, efficient realities with Neptunus, where nearly 90 years of expertise meets cutting-edge modular building technology, delivering permanent-quality performance with temporary flexibility.

Common Questions Answered

1. How can I improve thermal comfort in a temporary building?

Proper insulation and climate control work together to maintain stable temperatures. Zoning lets different areas, like offices and warehouses, stay at their ideal temperatures independently. Air-tight seals stop draughts, whilst weather sealing keeps wind and rain out, eliminating cold spots and condensation.

2. How do you control noise in temporary spaces?

Noise control is achieved through a combination of insulated panels, acoustic absorption materials, ceiling tiles, fabric wall panels, and appropriate flooring. Quiet HVAC systems with vibration isolation complete the package. The BBC Earth Experience completely blocked central London traffic and pedestrian noise whilst delivering pristine audio quality, proving temporary structures match permanent buildings in acoustic performance.

3. What’s the planning process for temporary spaces?

Here are the following steps for the planning process.

- Step 1: Define your needs

- Step 2: Assess your site

- Step 3: design

- Step 4: Get approvals

- Step 5: Manufacture

- Step 6: install and handover

Timeline: 3-6 months, including approvals, or 4-8 weeks fast-track for shorter projects. Neptunus supports clients through the approvals process by assisting with regulatory requirements and paperwork, while responsibility for submissions remains with the client.

4. How do temporary buildings handle extreme weather?

Engineered for UK wind loading zones and regional snow maximums, subject to the use of a solid roof system. Sealed panels with proper drainage. Additional bracing and corrosion protection for coastal conditions—our Hull dockside warehouse used reinforced wall to meet upgraded specifications. Insulation manages temperature extremes. Raised floors address flooding. Structural calculations include safety margins. Compliance with Eurocodes and British Standards ensures safe weather resistance.

5. How customisable are temporary structures?

Extensively. Bay increments allow size customisation. Partition systems create multi-deck. Finishes integrate branding and corporate identity. Glazing, flooring, climate, and electrical systems are all customisable. Specialist features include clean rooms, cold storage, and acoustic treatments.